Send In The Reinforcements!

My OpenSCAD experience has improved as I've become more familiar with how it works. Thread design was a really good exercise, and made me much more aware of general thread geometry and tolerances, as well as some rendering limitations of OpenSCAD.

There are some things I'd probably change in OpenSCAD, like have negative volumes so that those could track at the module level, but nothing seems to be terribly missing. And since it's a language, you can always add your own primitives by including their files. Some features feel really clumsy at first - because they are! - but like anything you get used to it. Final render times can be on the order of minutes, but the preview is usually pretty snappy. If you're familiar with C / C++ syntax, you will immediately be familiar with OpenSCAD coding syntax, as they are largely equivalent. And text file input means you can document critical design elements (like parameters) to your heart's content in the comments, a gigantic advantage over GUI type CAD entry.

I'm using the "hull" quite a bit lately, coupled with the "cylinder" which allows for different top and bottom radii, to form face plates, ribs, LCD windows, etc. You see the "minkowski" used a lot, but I've read that it can be really slow to render, and I've gotten away from it with more direct basic forms. The biggest challenge in SCAD has been in adding a casual chamfer or fillet - sometimes you have to really think about how to do it, but usually there's a way that works well with the overall base geometry, and it never hurts (or, I should say, it always helps) to think about that some more.

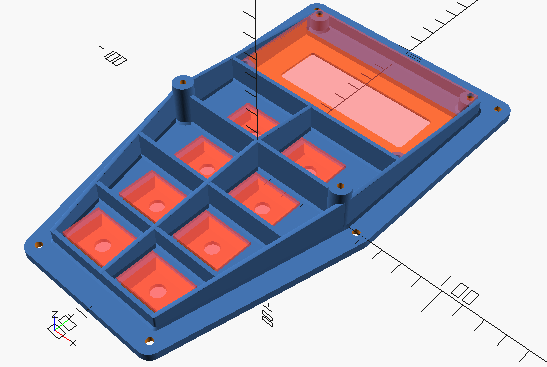

One thing I'm doing lately is CADing up any mating parts as transparent red/orange, and turning them on and off with a debug flag (along with some ECHOed fit dimensional reporting). Really useful for eyeballing fits and catching those sorts of mistakes. Here is my latest LCD & Encoders plate with the LCD module and encoder PWBs enabled:

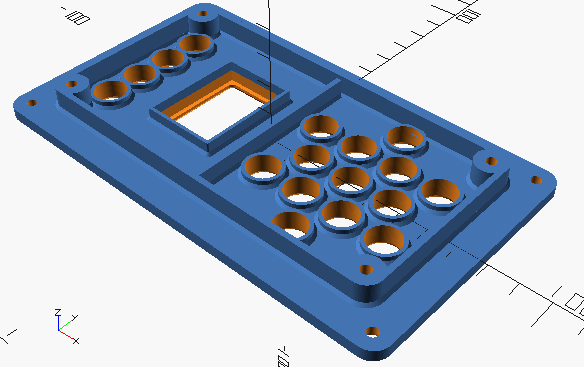

You can see that I've beefed up the reinforcing ribs around the LCD module. And here is my latest tuner plate:

Added some ribs around the perimeter, one down the center, and some skirting for the LEDs.

And here they both are printed in black PETG (I've since reduced the depth and angle of both the LCD and 7-segment LED windows, and I've applied Roger's red filter to the 7-segment):

Lordy, I wish I'd gotten into 3D printing a whole lot earlier for this project. I've wasted enormous amounts of time shopping for cabinetry related stuff. Even finding suitable prototyping enclosures, where you don't give a hoot what it looks like, can take forever. And 3D designing & printing is sorta fun, particularly if you're a control freak like me. But just sorta, as it certainly has downsides - much of the pleasure has been in the achievement of specific goals.

Pix are hot-linked from my D-Lev web site (https://d-lev.com/) storage, TW photo album upload seems to be broken?