"I don’t think there’s anything mystical about this. Dielectric losses will be greater if we place a dielectric in a region with the strongest electric field." - ILYA

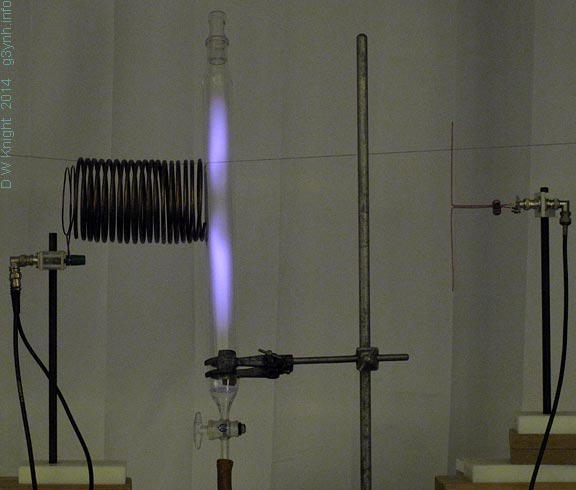

True, but these experiments are to find out the impact of various coil formers on Q. 3D printing really helps the winding process, particularly with finer wire on larger diameter formers.

"In the case of a solenoid, the strongest field is around the windings, i.e., outside. Inside, the field is practically zero. No field - no losses. Therefore, it doesn’t matter what the core is made of (unless, of course, it’s explicitly conductive)."

Hmm. I assume you're talking about the electric (rather than the magnetic) field? This says the E field inside a solenoid is proportional to the radial distance from the center, and the external field strength goes as 1/r: [LINK]. I've read that the magnetic field inside is uniform, and that the external magnetic field is largely zero. My understanding is that non-conductive former materials will introduce electric field losses greater than those of vacuum / air.