Another Ebay PCB supplier with free shipping from China, at about same price as Canadian boards.

Again, I have not used this supplier and cannot vouch for them.

From: Eastleigh, Hampshire, U.K. ................................... Fred Mundell. ................................... Electronics Engineer. (Primarily Analogue) .. CV Synths 1974-1980 .. Theremin developer 2007 to present .. soon to be Developing / Trading as WaveCrafter.com . ...................................

Joined: 12/7/2007

Another Ebay PCB supplier with free shipping from China, at about same price as Canadian boards.

Again, I have not used this supplier and cannot vouch for them.

Hi All,

My boards are on order from the excellent, or so it appears, manufacturer that Fred mentioned above. Give (((Fred))) a Hug. Ted Chen is the pcb contact.

Being my first board order ever, I ordered 2 oz copper instead of the common 1 oz. My logic is soldering durability (heat) by the amateur. I can see electric current issues for needing heavier copper but is there any advantage to 2 oz. for my very low current purpose?

Christopher

From: Eastleigh, Hampshire, U.K. ................................... Fred Mundell. ................................... Electronics Engineer. (Primarily Analogue) .. CV Synths 1974-1980 .. Theremin developer 2007 to present .. soon to be Developing / Trading as WaveCrafter.com . ...................................

Joined: 12/7/2007

A few factors influencing choice of heavier copper thickness for PCB's :

1.) Current carrying capacity - sometimes, particularly with power circuits (PSU / Amplifiers etc) it is not possible to get sufficient current carrying capacity in available track widths, going to thicker copper can help.

2.) Thermal dissipation - related to current carrying.. Lower resistance from thicker copper causes less heating of tracks.. Can also act better to carry heat away from components.

Disadvantages of heavier copper:

1.) For high frequency circuits, capacitive edge coupling can increase.. not likely to be a problem for most circuits.

2.) Heavier copper sinks more heat when soldering - there is more likelyhood of overheating component leads in order to get good tinning on the PCB.. This is particularly true when using higher temperature lead free solder.

Other:

Adhesion of copper to board is unlikely to be affected by the choice, however thinner copper will heat more rapidly, and if TC soldering equipment is not used and the person soldering the board is inexpierienced, the extra sinking from thicker copper could reduce the risk of adhesion failure - however, there is a high likelyhood that such application of excessive heat will damage components.

I personally prefer thinner copper, with lead/tin HASL coating - it is the easiest to solder. One can have big problems if RoHS (no lead) coating is used, but one uses lead solder, so if I must use RoHS boards, I go for the more expensive gold or silver finish, as lead solder wets well onto these - I always use high quality tin/lead solder (60/40) unless I am forced to do otherwise... Gold electroplated boards can be prototyped by me using lead solder, and built (pre-production testing) by the client using lead-free solder.. And they look more expensive! ;-)

This is one reason I went for the Canadian supplier - their standard board is not RoHS and uses lead/tin HASL.

From: Eastleigh, Hampshire, U.K. ................................... Fred Mundell. ................................... Electronics Engineer. (Primarily Analogue) .. CV Synths 1974-1980 .. Theremin developer 2007 to present .. soon to be Developing / Trading as WaveCrafter.com . ...................................

Joined: 12/7/2007

This is another cheap PCB supplier I have found - Certainly for the 10cm x 10cm boards the price is great. Postage is not free, so it may work out a bit more expensive than some others depending on your location - I think shipping to the UK from China is lower cost than to the USA.

http://imall.iteadstudio.com/open-pcb/pcb-prototyping.html

I have not used them yet - I have 2 batches of boards to get made in the next few weeks, and will send one batch to these people and another to Ted Chen, and advise.

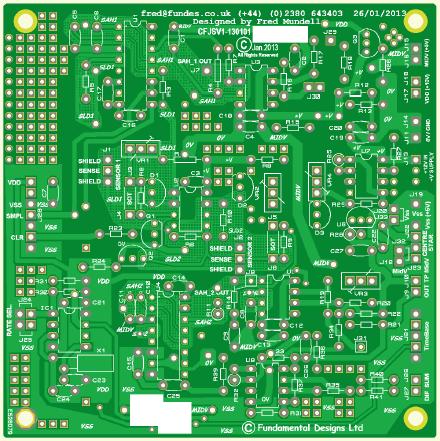

Below is a photo of some excellent boards I got from eurocircuits.com - I was forced to go for these expensive boards because I was let down by the "Canadian" (who are in fact Chinese) supplier, and Chinese new year made getting cheap boards impossible.

These boards, with postage (not including VAT) cost me 145.45 EUR for 10.. But I would have lost a valuable client if I had let them down by delaying delivery.

This board implements two capacitive sensors in differential mode, and two of these boards link to create a full high precision joystick for an extremely specific application .. A single board provides the electronics required to implement a capacitive "ribbon" controller which is the basis for a theremin related instrument I am developing, which has been "proved" on a crude breadboard but needed the extra precision implemented in this design .

It is really great when a client requires something and it dovetales with something I need to develop for myself - I tell them that I am working on something similar, and reduce their fees if they agree that I can use what I develop for them in some other application, and that, apart from their application, I own all rights to the design.. If they wont agree (as has only happened once) then I dont take on the job.. Most often they are more than happy.

Dear All ,

Best Regards,

Henry

Overseas sales Dept.

Shenzhen Tekn Energy Electronic Co., Ltd

Tel:+86-75529686982 Fax:+86-75529686981

Skype: henrypi2012

URL: www.szte-pcb.com

This may really be a dead topic but in case someone cares this is who I have been using recently.

OSHPark yields good quality boards with gold plating.

DFRobot yields good boards with off registration silkscreen. That isn't a problem unless you need the silkscreen for parts placement during construction. The pads stay down reasonably well if you try to replace parts however they will come off eventually.

PCBFabexpress makes good boards though I haven't used them in a while.

Goldphoenixpcb makes very good boards. I use them for large board prototypes. I also use them for quantities of 100 or more boards.

PCBWay is who I use most of the time for inexpensive low quantity prototypes. They probably use the same board manufacturer as DFRobot based on the bad registration of the silkscreen.

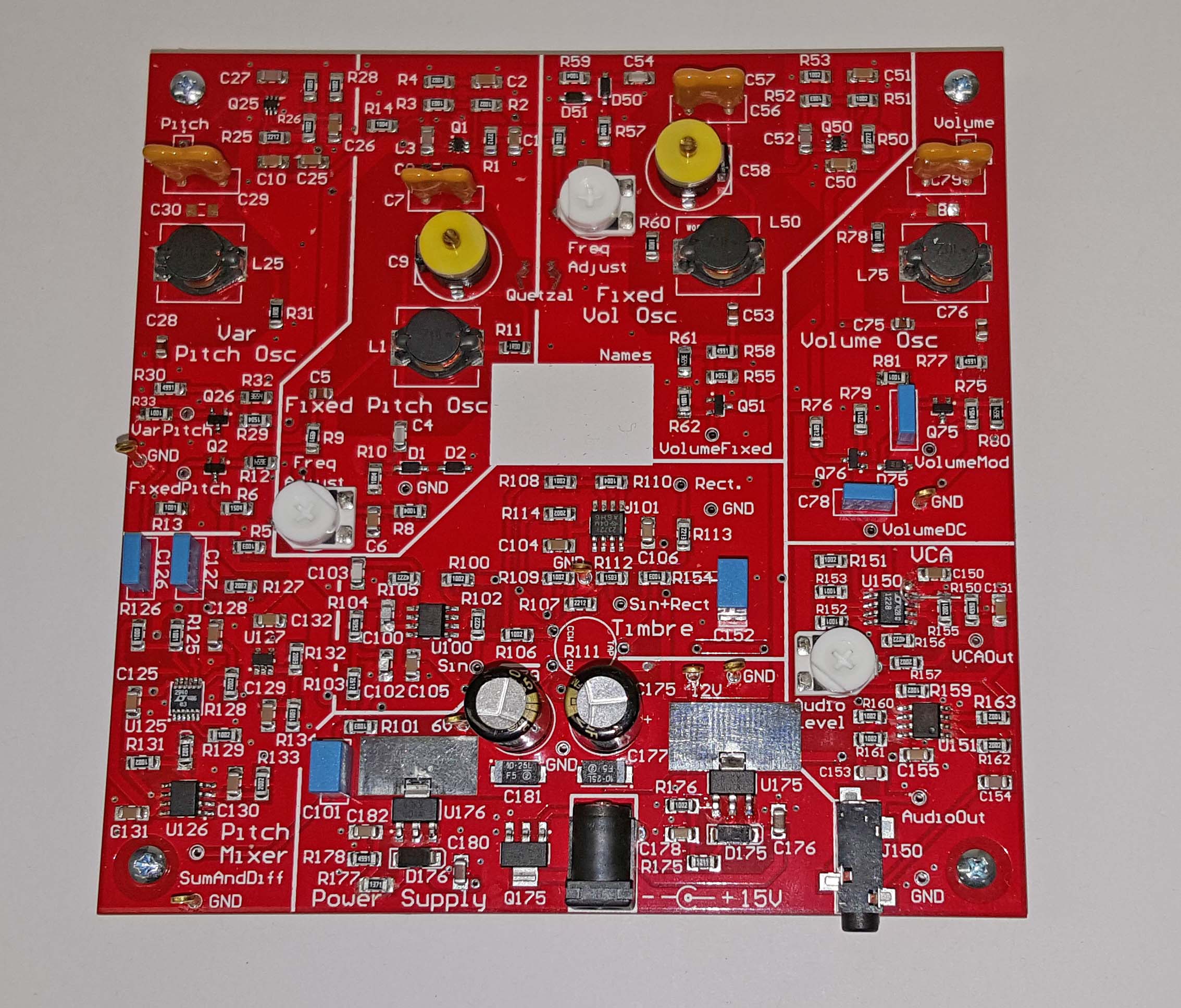

Here is an example of the board for the Rev 1 Theremin board that the students made in class. Sorry there are parts already soldered on because I was too lazy to take a picture of a bare board. I paid $116 for 25 boards delivered on a 4-5 day turn.

http://www.thereminworld.com/album/untitled-album/16070?photo=16071

Advanced Circuits out of Canada makes the best boards of this group. They have a deal for students so they get used a lot around the university here where I work. The sharpness of the pads even at small sizes is quite remarkable. They are more expensive than the others in this list.

markallie, thanks very much for the info!

And BTW, you can paste images from the photo albums into posts:

I think I'd aim for a more rectangular board, with the volume and pitch circuits more physically separate from each other at the ends, and the processing circuits in the middle (ala the Etherwave).

I tried to post the image but I guess I totally missed how to do that. I actually reviewed the posts on links and pictures. Please tell me what you did to post the picture. I do agree about the shape. The biggest problem is getting far enough from the antenna to make the fine adjustments with the variable cap and resistor for fine frequency tweaking with this layout. The oscillator interaction was essentially non-existent. I even tried keeping the oscillators all at the same frequency. Alas they had to be few kilohertz apart before they would not lock onto each other. The test was just for fun.

I received my breakout PCB today from jacoh, another board still to come. The quality and registration of the silkscreen is excellent and very cost effective. Will have a photo of the stuffed through hole PC board by the end of next week. If anyone wonders why I removed the schematic webpage it is because I have a major mood disorder. What I do is for Lev Sergeyevich Termen who needs to stop bothering me. (-'

I bought the EtherWave Standard kit today ($349) to install this mod, then I will just give it away and be done.

Christopher

Christopher, thanks for the jacoh PCB pointer! It's always very useful knowing other's experiences along these lines. What layout tool are you using? I tried Eagle for an hour or so and was so repulsed I really don't know how I might find my way back to it. Layout tools tend to be the worst for some reason.

You must be logged in to post a reply. Please log in or register for a new account.