Not for me. I mostly don't use batteries in pedals. I guess a lot of people do, because it's often an option. Is this going to drain batteries quickly?

Idea for Theremin Staccato Pedal

From: Eastleigh, Hampshire, U.K. ................................... Fred Mundell. ................................... Electronics Engineer. (Primarily Analogue) .. CV Synths 1974-1980 .. Theremin developer 2007 to present .. soon to be Developing / Trading as WaveCrafter.com . ...................................

Joined: 12/7/2007

" Is this going to drain batteries quickly?"

No - not unless one wanted to implement an "electronic spring".

Another of my "Tales from the White Hart" ! LOL ;-) ...

Back about 1976, I was an engineer in a recording studio / cassette manufacturing plant in Wimbledon (FPA Ltd) .. I met a musician (Multi instrumentalist but mainly synth) who mused that he wished there was a synth whos keyboard feel could be adjusted to suit the playing style... He wanted everything - a mono synth, poly synth, light touch, fully weighted .. all in one instrument.

He promised funding, put up a few grand, and Nova Synthesisers was launched (a partnership - NEVER get into a partnership.. If it had been a limited company I would have been ok.. ) (BTW - no relation to Novation which didnt then exist).. I got the basic synth guts operating (complete with a pre-MIDI digital interface - except it was parallel not serial) and started on the keyboard -

This was a modified Kimber Allen keyboard (back in the days when you could buy quality UK manufactured keyboards, and actually visit a manufacturer, get them excited and willing to do modifications on their standard product) I used inductive sensors on the keys (only one octave worth in the prototype) and had solenoids at the end (just beyond the key pivot point) replacing the spring usually there.

The sensor determined the key position, fed this via an ADC to a Z80 (I used a sinclair MK14 board at first) and fed back a current to power the solenoid - the idea was to map a key profile that dynamically altered the keyboard feel.

Development money didnt pay my bills, my partner/funder was full of big ideas and employing people to construct the casing and front panel (I think I still have a silk screen that cost hundreds of £ and was only used once - he was a moron, style etc was his sole focus - fine.. but we needed the synth working and to determine things like optimum keyboard length etc before we even thought about builing a box for the nloody thing!) and everyone took their money for the work except me as it was "my" project... Then things got nasty when someone else never got paid, and in the end the whole lot got carted off ("stolen" by creditors) and I got a job with Jeremy Lord Synthesisers and survived.

But the bottom line is that the technology I played with then may well be suited to a high-end pedal ! ;-)

Fred.

Well, I do think that the look of the thing is important. Why design a beautiful circuit and put it in a crappy box? But form should definitely follow function, so let's focus on the function for now. We have some people on TW who have designed and built wonderful theremin enclosures - I rather hope at some point - if we get that far - they will get involved.

Personally I'm obsessing a little bit over the name. As Pynchon wrote (I paraphrase from memory), "names are not magic, but the act of naming..." I woke up this morning with the idea of calling it The Rest, because, in active-off mode you really do "play the silences" and as Shakespeare wrote, in one of his few music lessons, "the rest is silence". Also because "say, do you play the theremin?" "Yeah, and the rest."

Another spring possibility - several small neodymium magnets in opposition to each other, repelling.

From: Eastleigh, Hampshire, U.K. ................................... Fred Mundell. ................................... Electronics Engineer. (Primarily Analogue) .. CV Synths 1974-1980 .. Theremin developer 2007 to present .. soon to be Developing / Trading as WaveCrafter.com . ...................................

Joined: 12/7/2007

"Another spring possibility - several small neodymium magnets in opposition to each other, repelling."

Yes - that could certainly work for a thin "pedal" .. Could perhaps also be incorporated in the sensing (hall) mechanism - having the sensor/s between two repelling magnets MIGHT result in a signal that has better linearity... (but it may not work at all ... is a weak "North" on one side and a strong "North" on the other the same as a South - North gradient ? - cant get my head 'round that)

"Spring force" wouldnt be adjustable - unless perhaps one had an abjustable counter-field magnet to effectively oppose magnets on one side........

LOL...

Gordon, im going to break off now - I will try not to comment or even think about any ideas you present, so if I go silent its not that im being rude! ;-) .... Its just that I cannot restrain myself - and am painfully aware that im hogging the show.

I will look back here perhaps after wednesday.

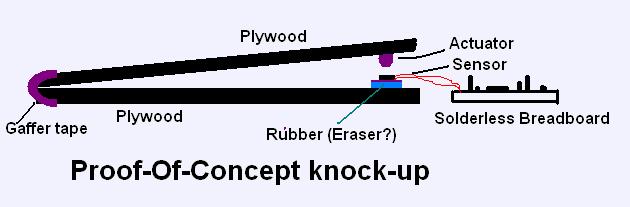

(I am also sort of wondering if this is getting too heavy - An extremely simple FSR 'pedal' mock up could be knocked together in a few hours - you would then have something to play with to test basic operation and perhaps give better insight into whats really needed.. I have wasted months on theory sometimes which I could have avoided by spending a day with some simple useless prototype that showed me that the core idea needed re-thinking)

Fred.

This info was moved to keep the pedal thread on target - go here as there is so much more that needs exploring!

Theremin meets the dan bau .mp3 500kb

Christopher

"My guess is that Taubman's second pedal is a dummy, to raise his other foot to the same height as the one on the active pedal, for comfort or balance." - GordonC

Ah, that makes a lot of sense.

"Why design a beautiful circuit and put it in a crappy box?"

What if we design a crappy circuit - could that go in a crappy box? ;-)

(moved VCA chatter to new thread.)

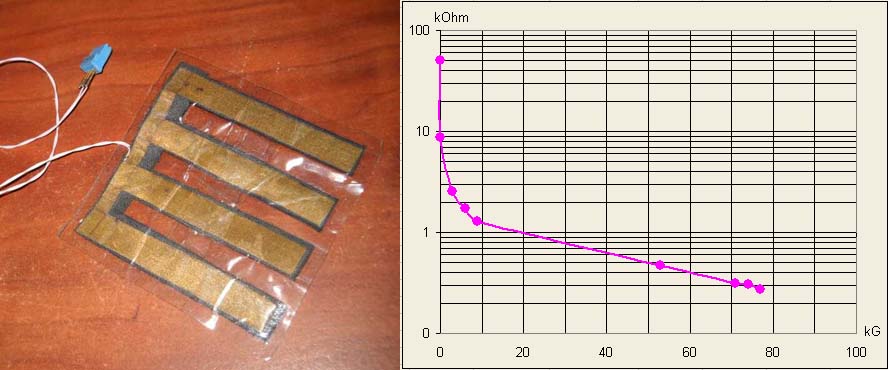

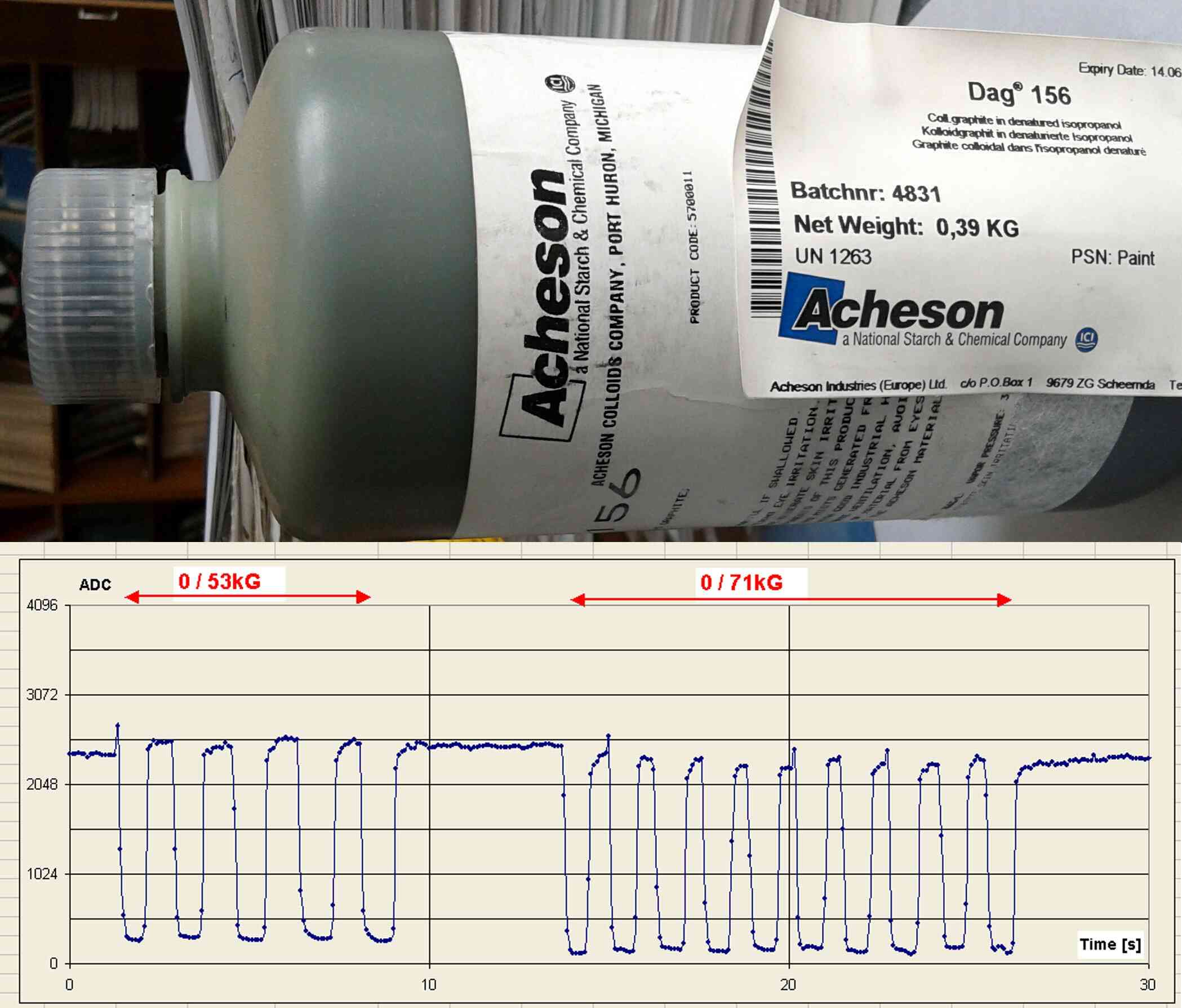

Once one of our divisions (chemical laboratory on my regular job) has received the bottles of colloidal carbon in isopropanol. For unknown reason the chemicals was not required and I took a couple of them for experiments.

My region of interst was the cheap pressure sensors. A lot of sensetive mats (for feet) were required for some DIY project.

My final solution was the sensor (7x7 cm):

The E-shaped electrodes (top and bottom) are cut from the brass mesh.

The central part of the sandwich is the cotton fabric which is previously impregnated by colloidal carbon and dried. The whole package is laminated by scotch.

Why E-shape?

1. Mechanical reasons (the clutch points are required on large surface)

2. Material savings (two of E-electrodes are obtained from the single square billet)

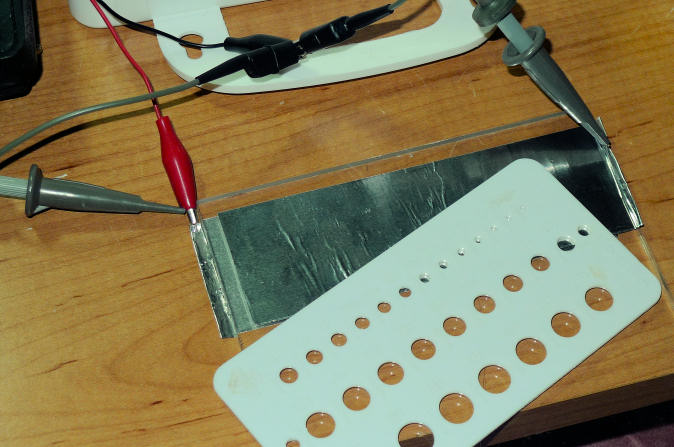

The dependence R vs Force was obtained by the primitive way as shown below (every bottle is +3 kg, plus my own weight, plus weight of my wife, plus combinations).

It was 2007... the project still temporally frozen...

Added.

The type of reagent is on the photo. Сonsumption is about 9 ml per 1 dm2.

Below are the data of cyclic load.

Just tried a quick & dirty capacitive "conducted away losses" experiment with stuff I had laying around. Stuck some 2" wide x 6" long aluminum tape to both sides of a 6" x 6" piece of 5mm thick Plexiglas. Placed a ~1mm thick piece of plastic over the top (a drill gauge, this insulator is for ESD and would not have holes in it in the finished product):

Drove the bottom piece of tape with a 100kHz, 5V p-p square wave from a function generator, looked at the signal on the top piece with a scope. Most of the action is with my hand touching the top plastic and a few mm away, but I clearly see 4V p-p with no hand, and 3.4V p-p with my four fingertips touching the top plastic. There appears to be a 60Hz component conducting via my fingertips, but unlike with Theremin FM stuff it should be easy to bandpass or lowpass filter this away to relative nothingness.

One could amplify the difference between drive and sense, then BPF, then detect / offset / invert / whatever to a VCA. Or get fancy and drive with pseudo-random noise and synchronously detect - this might help minimize conducted interaction of the drive signal with the Theremin's resonances as well.

I think for this kind of application ("staccato") you probably want snappyish action right at the pad and not a lot going on elsewhere.

Fascinating. Resistive and capacitive pressure sensors. Any more alternatives?

I've had a few moments to think about my feet. :-) It seems I can tap my feet about four or five times a second with a travel of about a centimetre. So average speed over the distance is within an order of magnitude of a tenth of a second per centimetre, accelerating from 0. (The record is held by Michael Flatley, 28 taps per second.) For responsiveness I would want a duration on the order of milliseconds rather than tenths of seconds. So squashing a very thin pressure pad would seem preferable to moving a pedal.

i also found specs for a machine that simulates footfalls, which brought up a question - how are different pressure sensing systems affected by the area of the object pressing them? Is that a factor to consider?

If I were approaching this in software, my approach would be to measure the pressure on the pad a very short time after the initial contact of the foot with the pad (would require calibrating to suit the maximum velocity a player is able and willing to impart to his foot) and use this to determine the speed of the ramp from mute to full volume (or vice versa) - more pressure = faster footfall = quicker ramp. While the foot remains on the pedal, change in pressure does not affect the volume. That is a task for the volume hand. However,the software would continuously sample the pressure, using the value a short time before the foot is removed to determine the speed that the volume is ramped in the opposite direction.

I have been listening to sounds run through an ADSR envelope on my computer, and there is a sweet range of speeds for the attack and the release which are not clicky but do shape the waveform momentarily in a way that makes a distinct start point to the sound (the release in the same zone just stops dead, which works nicely with some reverb, or a slower release can be made with the hand, which is fine.) I need to spend more time than I had available to figure out the optimal range more specifically, but I think the right way to do it would be with a prototype that allows me to set durations manually, rather than by measuring pressure. This would allow me to methodically try different settings in playing conditions.

After that we could look at reading the ramp durations from a pressure sensor, and consider how much benefit is actually to be had from that, rather than preset ramps. Does it justify the extra complexity?

Christopher - I like your "dan bau" sound very much. It's the sort of sound I have in mind. :-)

You must be logged in to post a reply. Please log in or register for a new account.