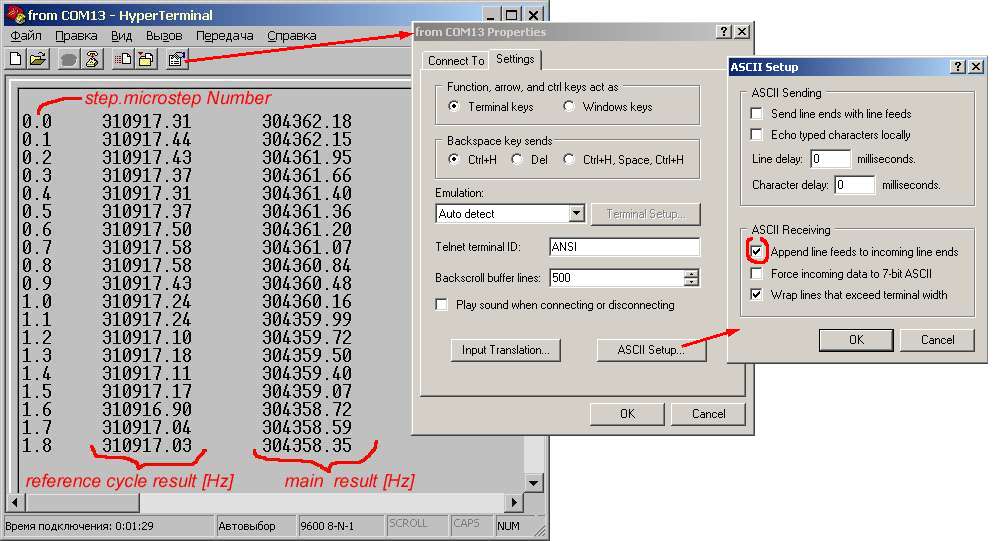

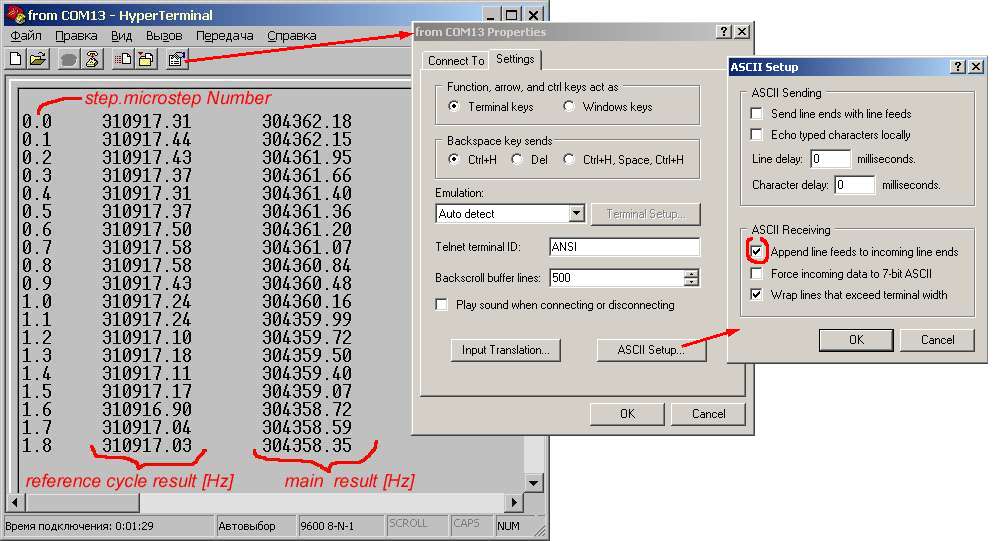

The data packet used (nothing complex, it's just a common text message):

<step number> <"tab"> <result 1> <"tab"> <result 2> <"end of line">

So, all you need for data logging is a standard communication application (like the Windows Hyper Terminal) and to press a "Start" key. Some extra setting can be needed for HyperTerminal:

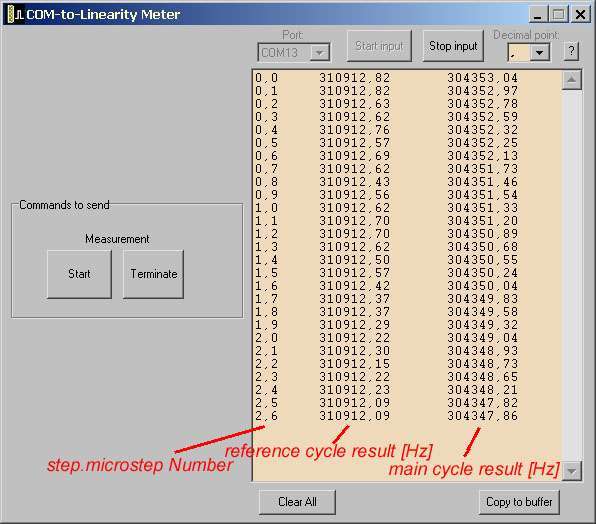

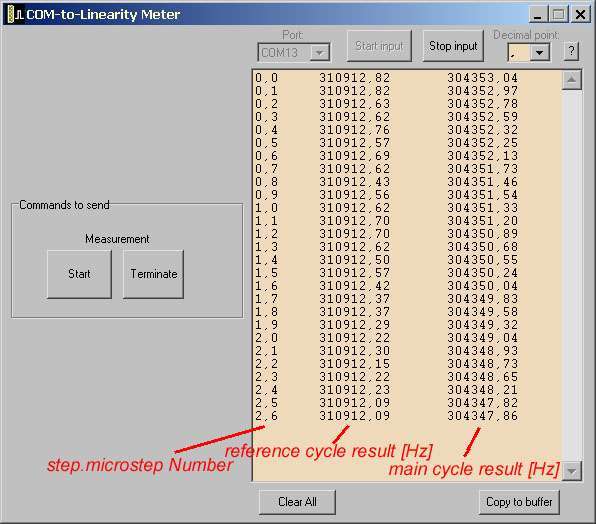

My own application which allows remotely starting measurement, plus some service functions::

The "Start" button sends the letter "S", the "Terminate" sends "T" (control board accepts and runs these commands).

After applying the "Copy to buffer" command (even "on the fly") the data can be directly pasted into Excel cells.

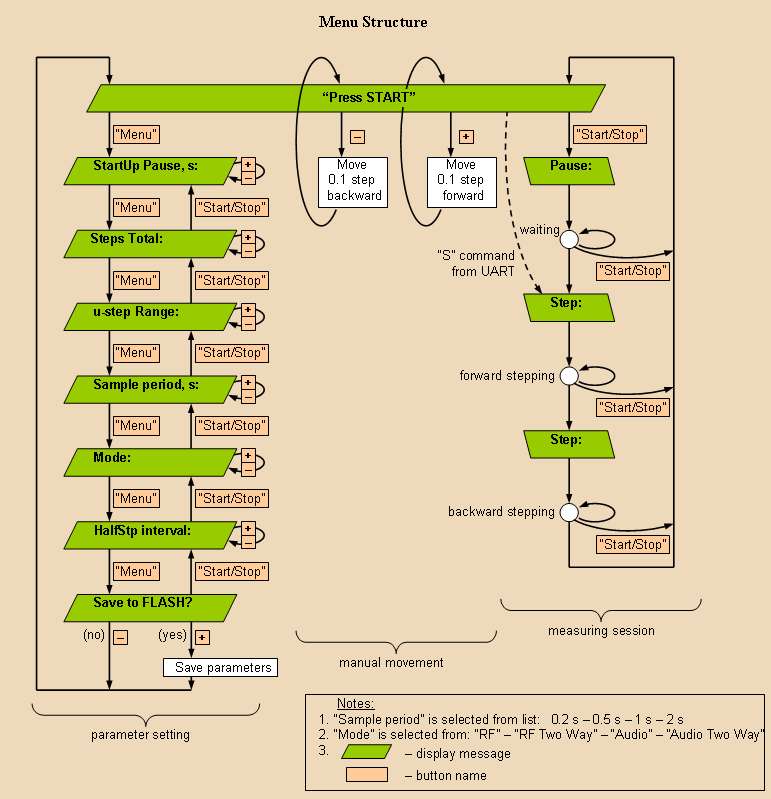

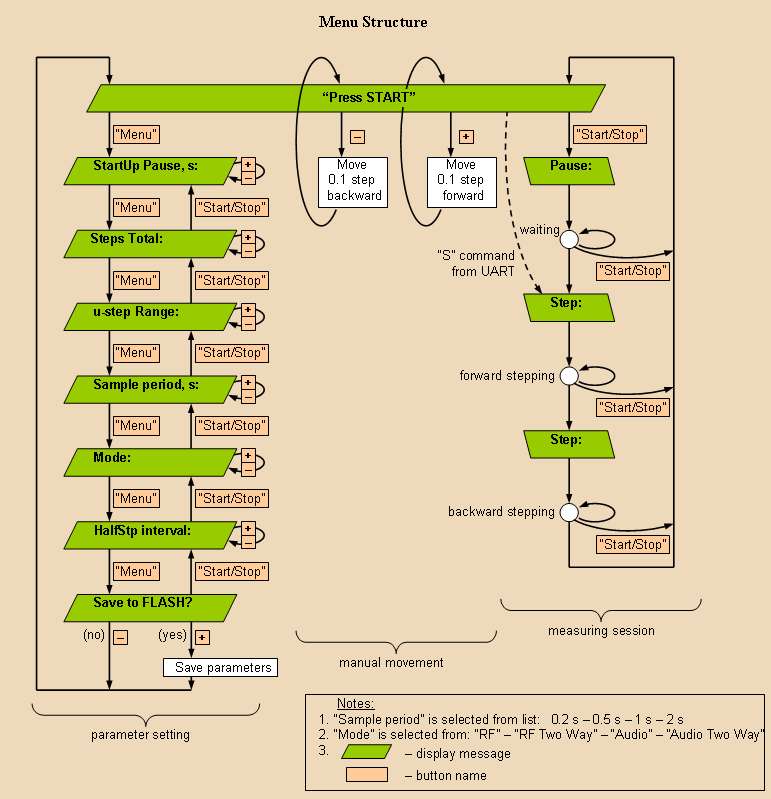

After evolutions, menu of control board looks like this:

Could you somehow mechanically (or electrically) damp it? - dewster

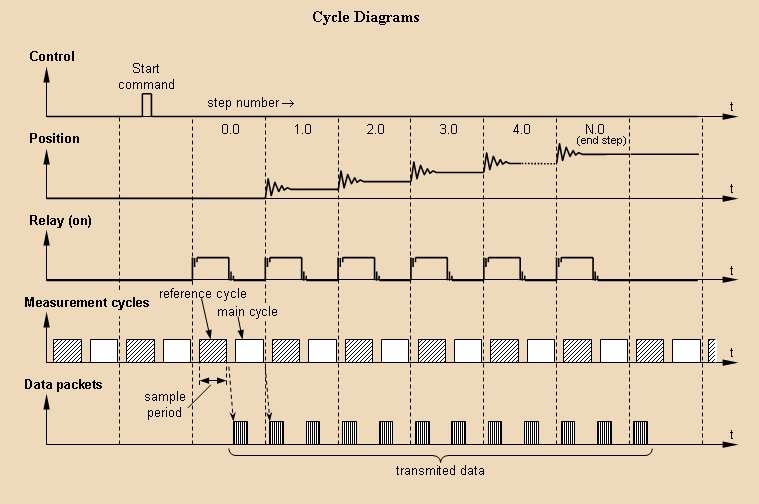

In microstep mode it is not so noticeable, but in the full step mode the amplitudes (by eye) reach a full step value and the relaxation time is about a second. Using a sample period 1 s and more (refer the Cycle Diagrams), it is possible not to worry about it. At the moment I am experimenting with the hard steel lever. A lighter "hand", I sure, will behave differently. "Sail effect" plus, maybe, usage of elastic materials.

As for the preventive, the special stepping algorithm was implemented: every step (or ustep = 0.1 step) is extra half divided. Two "halves" are used for acceleration and deceleration phases. With a properly set duration ("HalfStp interval"), the rotor finishes its movement with a zero speed and unwanted oscillations do not occur.

In practice, inhomogeneities of torque do not let to oscillations be completely suppressed. Nevertheless, such the algorithm makes them much smaller, and sometimes unwanted oscillations are completely disappear.